pulsed laser deposition.

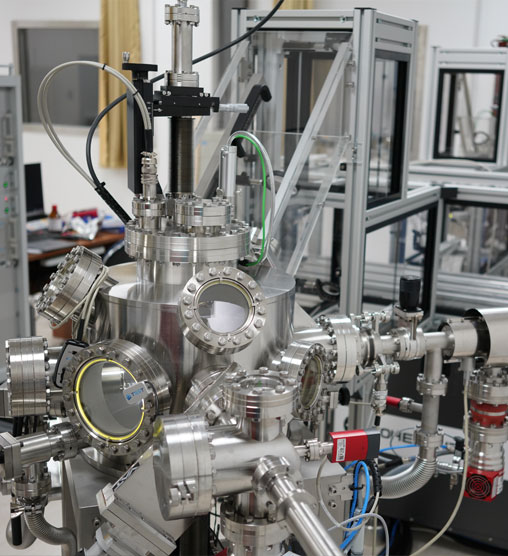

We are specialized in the design and production of customised, thin-film deposition equipment, with a focus on pulsed laser deposition (PLD). Our pulsed laser deposition systems ensure the best flexibility for RHEED studies and parameter reproducibility designed for thin-film research at atomic level. Our systems are ideally suited and field proven for research on a large variety of materials including complex oxides, from small to large area samples and wafer platforms.

-

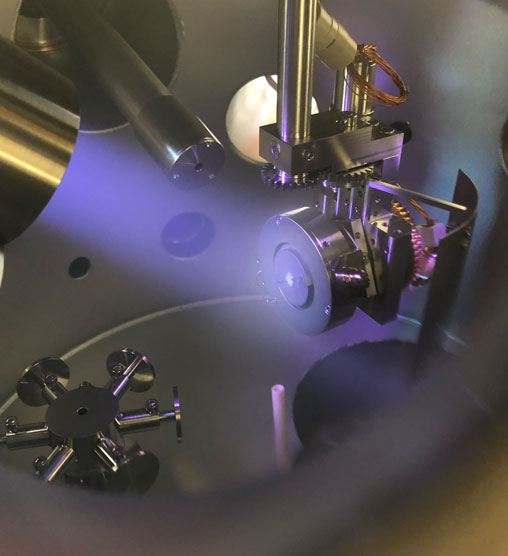

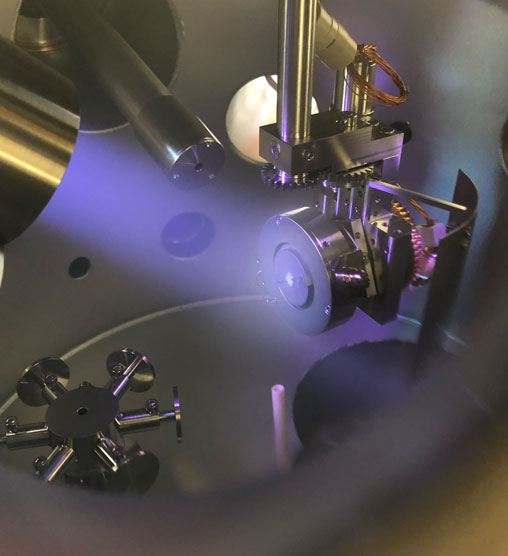

sample heating and manipulation

Depending on sample size and temperature requirements we offer: laser heating, resistive...

Read More

-

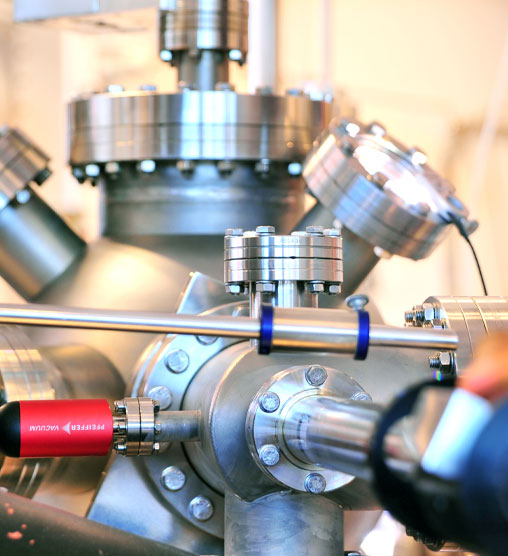

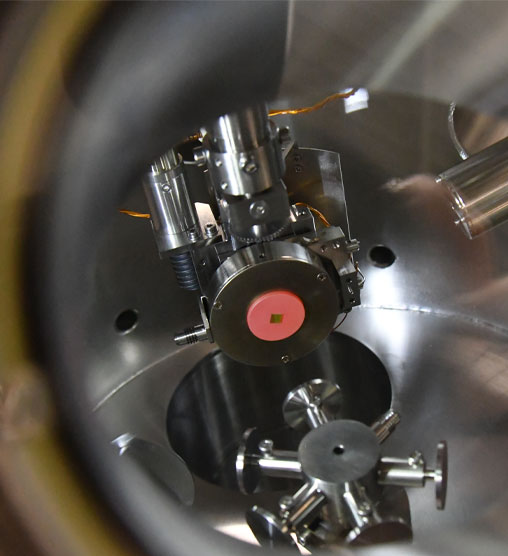

target handling

Target scanning ensures the lowest vibrations and lowest outgassing conditions.

Read More

-

laser beam delivery

Key in PLD, with a flexible layout, individual and optimal control and...

Read More

-

sputtering, evaporation, ion sources

It is often preferred to combine other deposition techniques with PLD, such...

Read More

-

sample heating and manipulation

Depending on sample size and temperature requirements we offer: laser heating, resistive...

Read More -

target handling

Target scanning ensures the lowest vibrations and lowest outgassing conditions.

Read More -

wafer scale PLD

TSST offers PLD system solutions for the growth of high quality materials...

Read More -

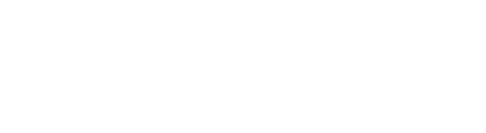

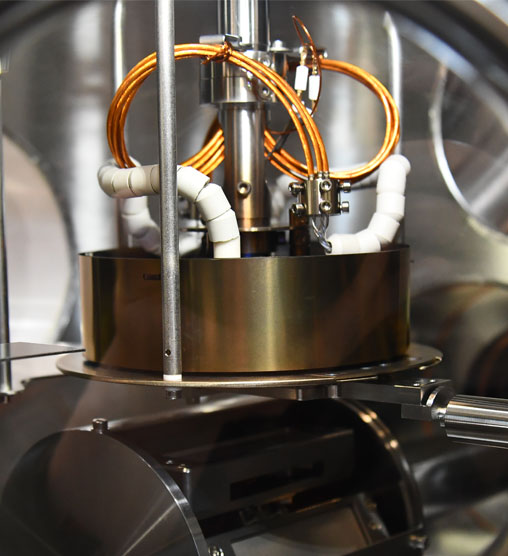

pressure and gas handling

TSST systems have a base pressure below 10-8 mbar, with true UHV...

Read More -

laser beam delivery

Key in PLD, with a flexible layout, individual and optimal control and...

Read More -

sputtering, evaporation, ion sources

It is often preferred to combine other deposition techniques with PLD, such...

Read More -

loadlock for sample and target transfer

To guarantee high vacuum quality, the system can be equipped with a...

Read More

highlights

- Single monolayer growth control with RHEED

- Down to 5.0×10-10 mbar base pressure

- Up to 1100°C growth temperature

- Integration of other PVD techniques

- Remote support, service and on site training by TSST engineers

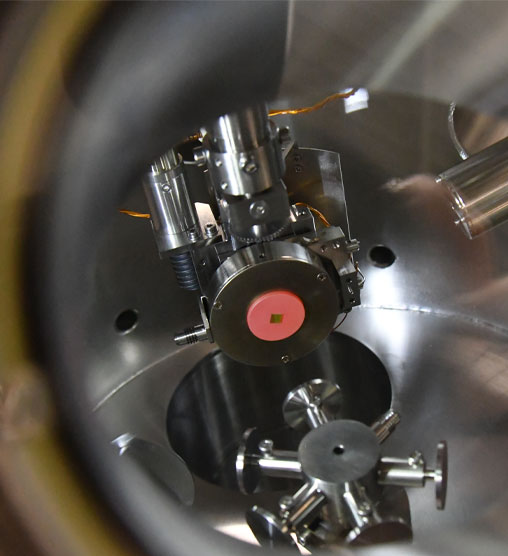

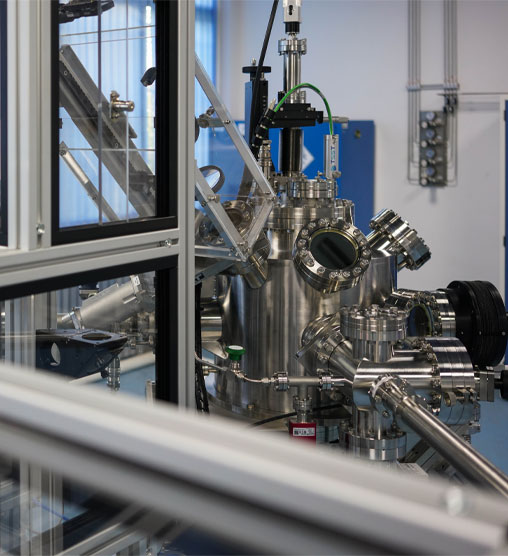

PLD systems and components.

Customised design and integration

Systems are adapted and integrated to existing beam lines, characterization tools and cluster setups, compatible with standard sample platforms such as flagstyle sample plates. We are experienced with the integration of other deposition equipment in a PLD system solution, including sputtering, evaporators and ion sources.

Customized cluster setups

One laser, multiple systems, PLD combined with other PVD systems.